Automotive

The Automotive Industry is highly dependent on specific metal works, products and services.

Aerospace

The Aerospace Industry is using a large variety of specific metal works, from spare parts to components.

Electronics

Specially machined metal parts are in high demand for the Electronics and EMS Industries.

Medical

The Medical Industry demands high quality services in order to sustain vital care services to patients.

Metal Services

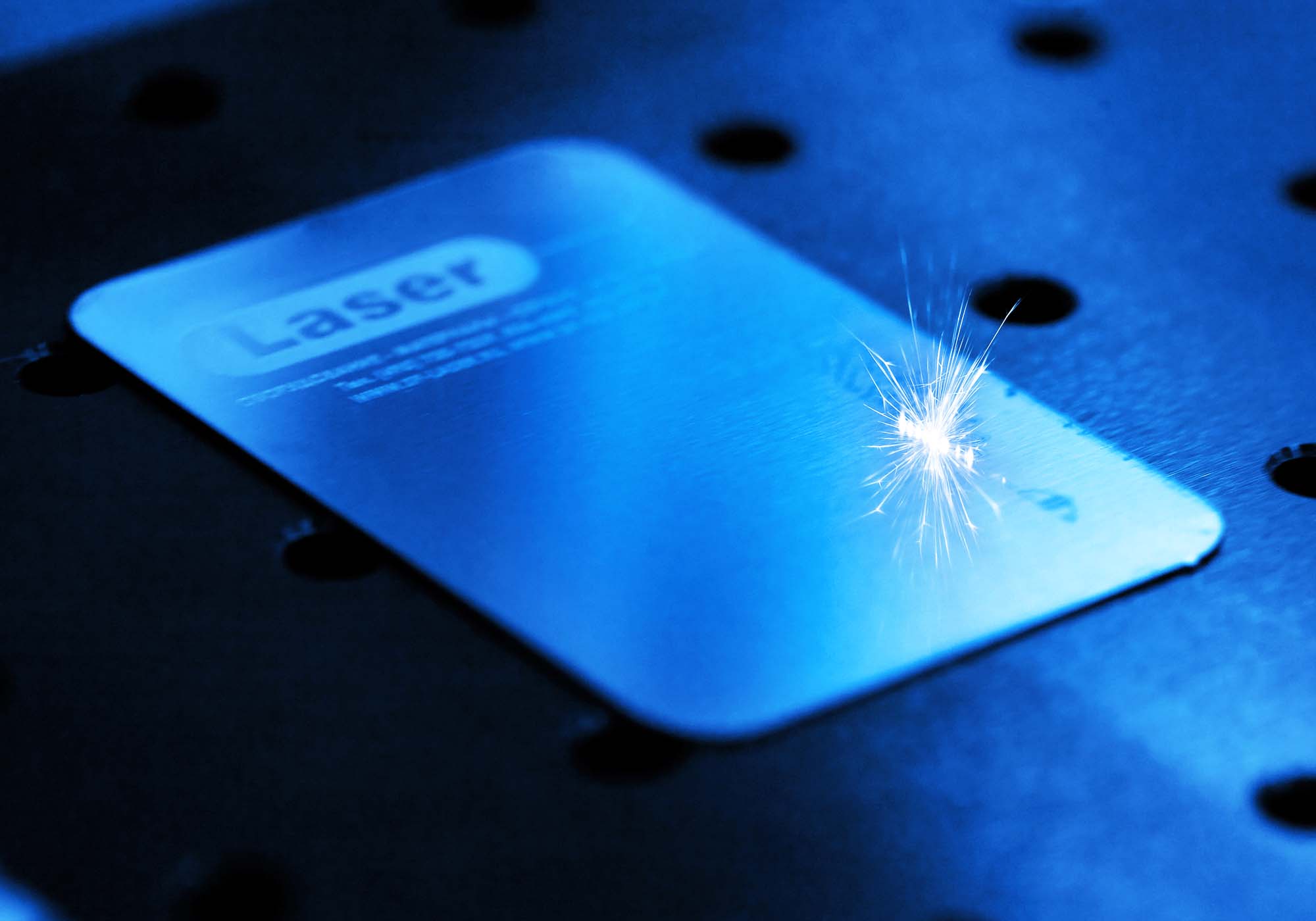

Router & Laser Cutting

Our equipment can cut stainless steel, aluminum, brass, copper, carbon steel, manganese alloy galvanized steel and electrolytic plate titanium alloy. The size of our laser table's work area allows us to cut metal sheets up to 3000mm X 1500mm. We employ nitrogen and oxygen for cutting, using a combination of both for an optimal quality and depending on the alloy being processed. We can produce 2D parts of almost any shape and our approach is more accurate and economical than plasma cutting. Having a fast rotation time, we can even use etching instead of cutting.

Metal Services

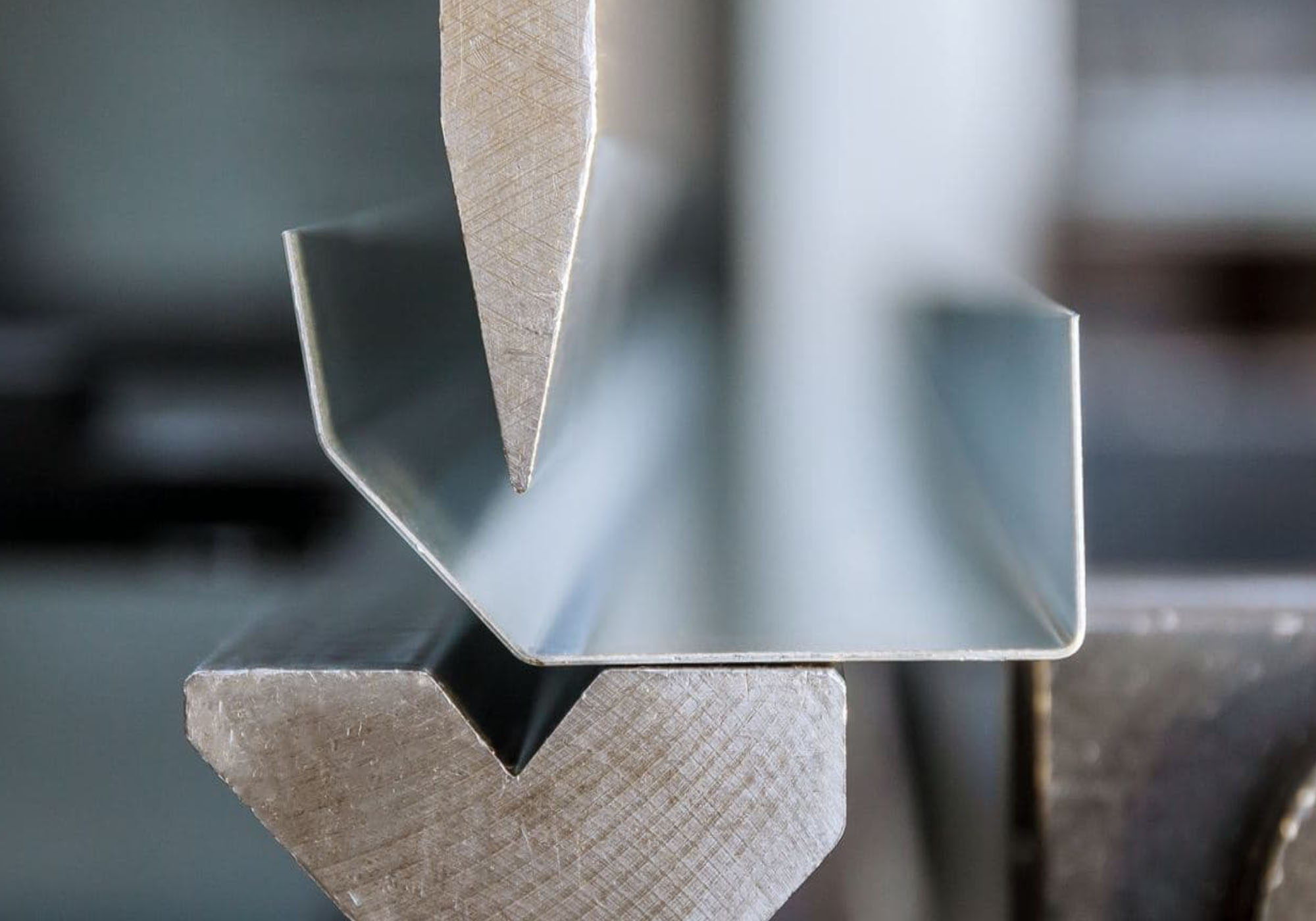

CNC Metal Bending

Our bending service provides a maximum bending force of 28 tons, with parts up to 1000 mm long and 10mm thick, with a guaranteed ram repeatability of 0.02mm. The powered back gauge can be programmed with up to 99 programs of 30 lines each. Thanks to the hybrid technologies, our machine can save almost 80% of the energy when compared to conventional hydraulic systems. CNC bending is an economical way of producing 3D parts from metal sheets. Our bent sheet metal parts are produced with hydraulic press brake, the process where a metal sheet is being pressed between a punch and die to bend it into the desired angle or shape. Common applications include brackets, enclosures, metal boxes and many others.

Metal Services

Metal Welding

As a full metal service, we also offer the welding process, by joining metal parts permanently and firmly with the minimal installation costs. We engage in all three commonly used types of welding: MIG, TIG, SPOT. Most common parts that we are welding during the manufacturing process include: metal boxes, trays, brackets, etc. We can join edges in almost every form configuration. Regarding the tooling equipment during welding, typically we are using stock goods, although custom jigs are made depending on difficulty of the project.

Metal Services

Metal Engraving

One of the biggest advantages when using the laser to engrave parts, is the precision and accuracy of a laser. This level of precision is found in all parts we produce and ensure that they are engraved to the highest standard. The most popular metal for laser engraving is stainless steel, but also cover materials like brass, aluminium, titanium, steel, copper & silver. Our equipment allows us to engrave special plastics like ABS, HIPS, Lexan, Polycarbonate, PEEK and Laminate.

Metal Services

Metal Finishing

LTHD provides precise and quality metal finishing services, such as: polishing, grinding, brushing. Metal polishing is a process that enhances the surface of a part by means of metal removal. Metal polishing is done through the use of abrasives, such as wheels, belts and abrasive media to ensure the best possible results. LTHD can also supply surface grinding for production runs of various sizes. We utilise various types of grinding media, cutting wheels, and machinery to achieve the right surface finish for your precision metal parts. All of our capabilities can be applied to just about any materials, including, but not limited to stainless steel, aluminium, and copper. Depending on the finish desired by the customer, we can go from bright to dull, or mirrored to a satin or brushed look.

Metal Services

Metal CAD/CAM

Our CAD/CAM department designs and prepares 2D drawings and produce 3D models. We'll work from scratch plans or computer files with tools to import, re-draft and develop your project with Design For Manufacturability and Manufacturing Resource Planning. We combine application functionality with advanced CNC programming for efficient utilization of punch presses and laser machines. Our team can provide a complete, comprehensive CAD/CAM solution for your products, services and samples. We can design your parts with amazing yield, process them for cutting, punching and bending.

Customer Support

Need Help? Chat with us on Whatsapp